You’ve seen them driving around town, and hopefully by now you’ve probably encountered a few electric vehicles, or EVs, in your shop. If you’re one of the those that’s still apprehensive about servicing these vehicles, you’re not alone.

EVs have only been around since the early 2000s, but they have become one of the fastest growing new car segments. While they still only make up 3.4% of the vehicles on the road today, this percentage grows every year. As these vehicles age, they will require repairs and maintenance like any other conventional automobile, but if you’ve never worked on these vehicles before, or are just hesitant to take them on, here is some background on EVs to get you up to speed.

Types of Electric Vehicles

EVs: Sometimes referred to as BEVs, Battery Electric Vehicles are the easiest to identify of the bunch. They do not have any sort of internal combustion engine (ICE), and rely entirely on a high voltage battery and electric motor to power the vehicle.

Owners of these vehicles need to either charge at home, or rely on a system of charging stations. Because these vehicles are solely powered by a battery, this battery must be fairly large to give the vehicle a reasonable range.

Example of these vehicles: Nissan Leaf, Tesla, Chevy Bolt, Ford Mach E

HEV: Hybrid Electric Vehicles have both an internal combustion engine and a high voltage battery that powers an electric motor.

These vehicles do not have the ability to plug in to charge their high voltage battery; instead, they rely on their internal combustion engine to charge this battery either by using excess power from the engine or regenerative braking.

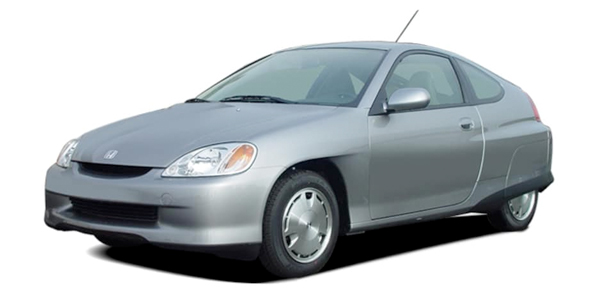

Example of these vehicles: Toyota Prius, Honda Insight, Ford Fusion Hybrid

PHEV: Plug-in Hybrid Electric Vehicles are very similar to Hybrid electric vehicles in that they both have an internal combustion engine and a high voltage battery.

However, with these vehicles the battery is typically larger, which allows them to travel up to 40 miles on battery power alone. These vehicles can charge their battery not only through their engine, but also by plug-in and commercial chargers.

Example of these vehicles: Chevy Volt, BMW 3-series Hybrid, Toyota Corolla and Rav4 Hybrid

Charging

Now that we’ve covered the most popular styles of EVs, it’s important to understand how these vehicles are charged. While all Plug-in EVs and BEVs can be charged through a simple 110-volt outlet found in your shop or garage, this may not be the quickest way to charge them. This can be an issue if you’re working on an EV in your shop and need to take it on a road test in order to duplicate a noise or complaint. Charging through a 110v outlet may take hours for just 20 miles of range. So make sure to have a designated area where you can park the vehicle and it’s out of the way of the rest of the shop.

If you’ve embraced working on EVs and have a lot of customers that own them, you may also consider purchasing a level-2 charger. These chargers require a 220-volt outlet (same plug meant for an oven or electric dryer) but will charge up to 3 times faster than a regular charger. Not only would this help reduce the anxiety of test driving an EV that is low on charge, but it could also be a perk for a customer to consider when looking for a shop to service their vehicle.

While full EVs may not have an internal combustion engine, and in general have a lot less moving mechanical parts, there are still quite a few serviceable items on these vehicles.

Safety

When most people think of EVs, they immediately think of electricity and the high voltage system that powers the vehicle. A high voltage system is considered any voltage that is capable of causing injury or damage – on an automobile this would be about 60v DC.

Most hybrid EVs operate at voltages around 200 volts, while most full BEVs run voltages upwards of 350 volts. When working around these high voltages, it’s important to be as safe as possible. That means making sure you have the right equipment for servicing these vehicles.

Training: High voltage training, whether online or in-shop, is a critical component of working around EVs. While much of the safety information is going to be vehicle-specific and found in the factory service information, it’s important to have a good general understanding of electricity and learn basic shop safety when around high voltage. By having the proper training, you and your techs will be able to immediately identify high voltage hazards that may arise, as well as know how to administer the right type of aid should an emergency occur.

Safety Gloves: While most technicians are used to wearing latex or nitrile gloves already, high voltage safety gloves aren’t meant to just keep your hands clean, they are specifically intended to insulate against high voltage and protect the user from electric shocks. These gloves are usually made of thick rubber and come in different sizes. Make sure to always keep at least a pair of these gloves in the shop, and to periodically check them for holes and tears. While you may not need these gloves for routine services, most manufacturers recommend using safety gloves any time servicing or replacing the high voltage battery or associated components. If you’re unsure of when to wear safety gloves, always consult the factory service information.

Insulated Tools: If you find yourself servicing EVs on a regular basis, a good investment would be a set of insulated hand tools. These tools not only protect you from electric shocks, but also protect the vehicles vital components from shocks and arcs. Insulated tools are either made of composites or have a thick plastic layer of insulation. This layer of insulation prevents short circuits that can occur when a hand tool touches two components at different sides of the circuit.

While it’s no longer necessary to replace the engine oil and filter, other fluids still have to be serviced, including brake fluid, coolant, and gear oils (all of which have similar service intervals as their ICE vehicle counterparts).

Electrical Equipment: Chances are you already have a digital multimeter that is capable of handling the high voltages found on an electric vehicle. If not, it would be a good time to update your existing multimeter with one capable of at least 500v. If you do already have a capable multimeter, just make sure that your test probes and cables are also rated high voltage whenever performing tests on the high voltage battery or charging system.

Servicing and Maintenance

Now that we’ve covered some of the basics surrounding EVs, it’s time to focus on how these vehicles can be a revenue stream for your shop. While full EVs may not have an internal combustion engine, and in general have a lot less moving mechanical parts, there are still quite a few serviceable items on these vehicles. While it’s no longer necessary to replace the engine oil and filter, other fluids still have to be serviced, including brake fluid, coolant, and gear oils (all of which have similar service intervals as their ICE vehicle counterparts).

Another thing to keep in mind when servicing these vehicles is that they tend to be quieter than conventional vehicles, which means that engine, road, and wind noise are all more obvious while driving. This not only creates an opportunity to be able to diagnose noises issues more accurately, but also provides an upsell opportunity. Make sure to perform a thorough road-test any time you’re servicing an EV. EVs have longer service intervals, and also tend to have more overdue maintenance when they finally roll into the shop. The most common items include tires, cabin air filters, lights/bulb, and windshield wipers.

Overall EVs do require less maintenance than their ICE counterparts, but there is no reason that you should avoid servicing them altogether. By understanding how they function, and taking the proper safety precautions, EVs can contribute to your overall profitability.

Look at our entire suite of products to determine your shop’s needs.

If you would like to read more articles like this one please subscribe to ALLDATA News.